Polypropylene Applications

Fabri-Tech uses polypropylene material to create an array of custom made parts and components for our customers. Polypropylene material is very versatile and features many characteristics that make it ideal for our manufacturing processes.

Polypropylene material is highly resistant to fatigue, corrosion, freezing, and chemical leaching. It is one of the stronger polymer materials, but can also be very flexible. Polypropylene material is popular for a range of applications, some of which include:

- Medical & laboratory implements

- Food containers

- Disposable bottles

- Car batteries

- Rugs & carpet

- Ropes

- And more

Polypropylene foam is widely used in model aircrafts and other radio controlled hobbyist vehicles.

Custom Polypropylene Material Converting Services

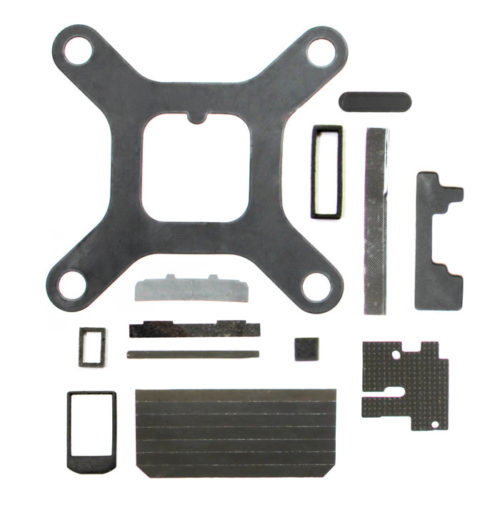

Fabri-Tech uses ITW Formex polypropylene material to manufacture custom insulators. This is due to polypropylene’s outstanding dielectric properties and its exception resistance to water (less than 0.1% moisture absorption). It is readily bendable and formable, and is easy to score. Polypropylene is also readily bendable and formable, and is easy to score with a superb UL flammability rating. Polypropylene similarly bonds well with most adhesive technologies, and is highly impact resistant.

These characteristics make polypropylene material ideal for our custom converting services, as it can be fabricated into any size, shape, or design that your application requires. Every polypropylene product Fabri-Tech manufactures is completely customizable to match the requirements of your unique design. We can create and customize to the limits of your imagination.

Contact Fabri-Tech Today

Contact us for more information on our custom polypropylene material, or request a quote today.