At Fabri-Tech Components, Inc., materials are at the center of everything we do. Every part we produce begins with a careful choice of material that meets your exact functional and performance goals. Whether you need heat resistance, insulation, thermal, vibration control, or gap-filling properties, the right material selection guarantees consistent and dependable results.

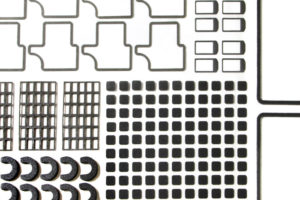

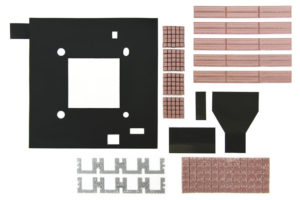

Our material converting capabilities cover a wide range of substrates, from foams and films to adhesives, fabrics, and specialty polymers. Each is processed with accuracy and attention to your product’s specific needs. The result is a finished component that performs exactly as expected — efficient, reliable, and built for your industry’s requirements.

Engineered Materials That Deliver Results

Selecting the right material starts with understanding your project’s purpose. At Fabri-Tech, we don’t rely on one-size-fits-all solutions. We consider performance, environment, temperature exposure, electrical insulation, and mechanical strength. By combining that information with our converting expertise, we help you achieve parts that perform consistently in real-world applications.

Our materials are sourced from trusted suppliers who provide consistent quality. From high-temperature polymers to soft, flexible foams, we convert a wide variety of materials for industries such as electronics, medical, automotive, aerospace, and industrial equipment manufacturing.

Silicone Foam – Flexible and Reliable Performance

One of the most versatile materials we work with is silicone foam. This material is ideal for customers who need high performance in demanding environments. It handles both heat and cold, resists compression, and maintains flexibility over a wide temperature range.

Silicone foam is widely used for sealing, vibration isolation, cushioning, and thermal protection. It’s especially effective in environments where temperature extremes or exposure to moisture can cause other materials to fail. Our converting capabilities allow us to die-cut and laminate silicone foam to tight tolerances, creating consistent and repeatable results every time.

If your product requires long-lasting cushioning or insulation in a high-heat environment, silicone foam is a dependable choice. We can help you select the right density, thickness, and adhesive combination to meet your design requirements.

Polyimide Films and Insulating Materials

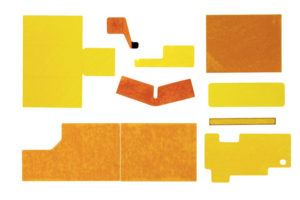

Another essential category in our materials lineup is polyimide. Known for its outstanding electrical insulation and mechanical strength, polyimide is a top choice for applications that demand high temperature resistance and long-term reliability.

We often work with Kapton polyimide, a branded version developed by DuPont. It’s known for its stability and performance under extreme heat. Kapton polyimide films are used in flexible circuits, insulation barriers, sensors, and aerospace components because they retain their physical properties across wide temperature ranges.

Fabri-Tech has extensive experience converting polyimide and Kapton polyimide films through precision slitting, laminating, and die-cutting. Whether you need fine insulation layers for electronics or complex shapes for industrial systems, we deliver parts that fit precisely and perform reliably.

These films can also be combined with adhesives, foils, or other substrates to create multi-layer constructions that meet specific dielectric or thermal performance goals. Our team helps you choose the best configuration for your product’s needs.

Polyurethane Foam Insulation – Lightweight and Durable

Polyurethane foam insulation is another material frequently used in our converting processes. It’s valued for its strength, flexibility, and ability to reduce thermal transfer. This foam is commonly used in HVAC systems, enclosures, automotive components, and energy-efficient equipment where temperature control and vibration reduction are important.

Fabri-Tech converts both open-cell and closed-cell polyurethane foams. Open-cell foam provides breathability and sound absorption, while closed-cell foam offers better sealing and moisture resistance. Depending on your needs, we can cut, laminate, or combine these materials with adhesive backings to create insulation pads, gaskets, or vibration-dampening parts.

Polyurethane foam insulation helps protect sensitive components from heat and mechanical stress while keeping overall system weight low. Its versatility makes it an excellent fit for many industries, and our ability to convert it precisely means your finished parts will fit perfectly into your production process.

A Wide Range of Additional Materials

Beyond silicone, polyimide, and polyurethane, Fabri-Tech works with a large selection of other engineered materials. Each offers different benefits depending on the function and environment of your application. These include:

- Pressure-Sensitive Adhesives (PSAs) and specialty tapes for bonding and assembly

- Polyester, polyethylene, and polypropylene films for electrical insulation and labeling

- Nomex aramid paper for high-temperature and dielectric applications

- Thermal interface materials (TIMs) for heat transfer control

- Foils for shielding and reflective insulation

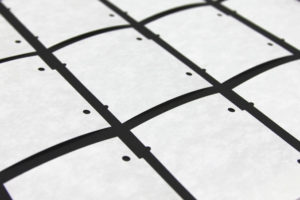

- Fabric mesh and nonwoven materials for filtration and structural reinforcement

Many of these materials can be laminated or combined to create multi-functional composites. For example, a foam layer can be bonded to an adhesive or foil to produce a thermal and acoustic barrier. Our team can help you decide which material combinations deliver the best balance of cost, performance, and manufacturability.

Material Selection Expertise

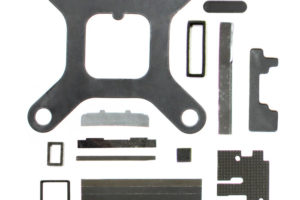

Choosing the right material is an important step in your product design process, and our team is ready to assist at any stage. We analyze the working environment of your part — temperature exposure, compression requirements, electrical insulation needs, and chemical compatibility — before recommending a material solution.

Our engineers and technicians use advanced converting techniques such as precision die-cutting, rotary cutting, laser cutting, slitting, and laminating. Each process is optimized for accuracy and repeatability, so your parts maintain the same performance from the first piece to the last.

Quality control is built into every step. We monitor dimensions, material integrity, and bonding consistency to maintain the highest standards. Whether you need a single prototype or a full production run, you can expect precision, repeatability, and consistent material quality.

Why Customers Choose Fabri-Tech

Customers across industries choose Fabri-Tech because of:

- Simplified Material Sourcing and Converting: We manage the entire process — from material selection to processing and finishing — so you can stay focused on your product’s performance and assembly.

- Extensive Industry Experience: With decades of hands-on experience, our team supports both established manufacturers and new product developers with dependable converting solutions.

- Versatile Capabilities: We handle projects that require thermal insulation, cushioning, EMI shielding, moisture resistance, and more — delivering consistent results for every application.

- Reliable Supply Chain Partnerships: Our strong relationships with material suppliers help maintain steady lead times and consistent quality, even on complex or high-volume orders.

- Efficient and Cost-Effective Processes: Through optimized converting methods, we help reduce waste, shorten production cycles, and control overall costs.

- Responsive and Knowledgeable Support: Whether you’re launching a new design or improving an existing one, our team offers practical guidance and fast, clear communication from start to finish.

Contact Fabri-Tech Components, Inc. to discuss your project or request a quote. Our engineers will help you find the right material solution and conversion method for your next build.